Powerful Hot Air Flow – Exceptional Cleaning & Drying Performance

The Torgos dryer uses a massive stream of hot air under high pressure, delivering up to 80 m³ of air per minute. While the air reaches temperatures of up to 600°C, its high velocity ensures that the road surface is only warmed to a safe 40–50°C. This prevents damage while still achieving deep and effective drying.

Thanks to the large volume of air, the Torgos dryer not only dries but also cleans the surface thoroughly, removing moisture, dirt, and debris with ease. Its drying efficiency is unmatched by any other dryer on the market, making it the ideal solution for professional road marking and surface preparation.

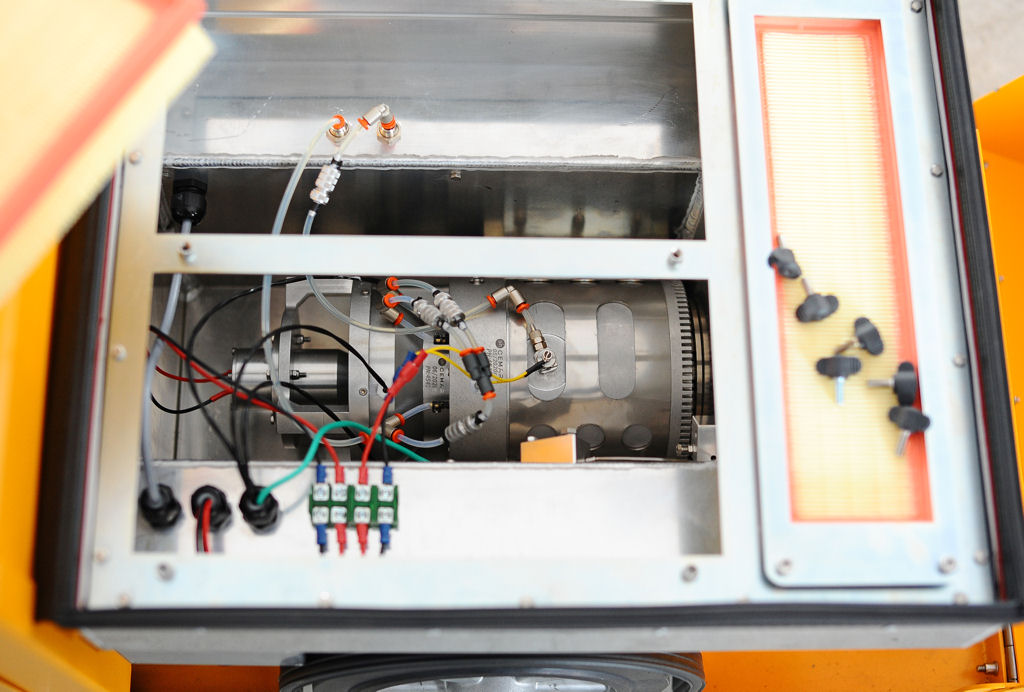

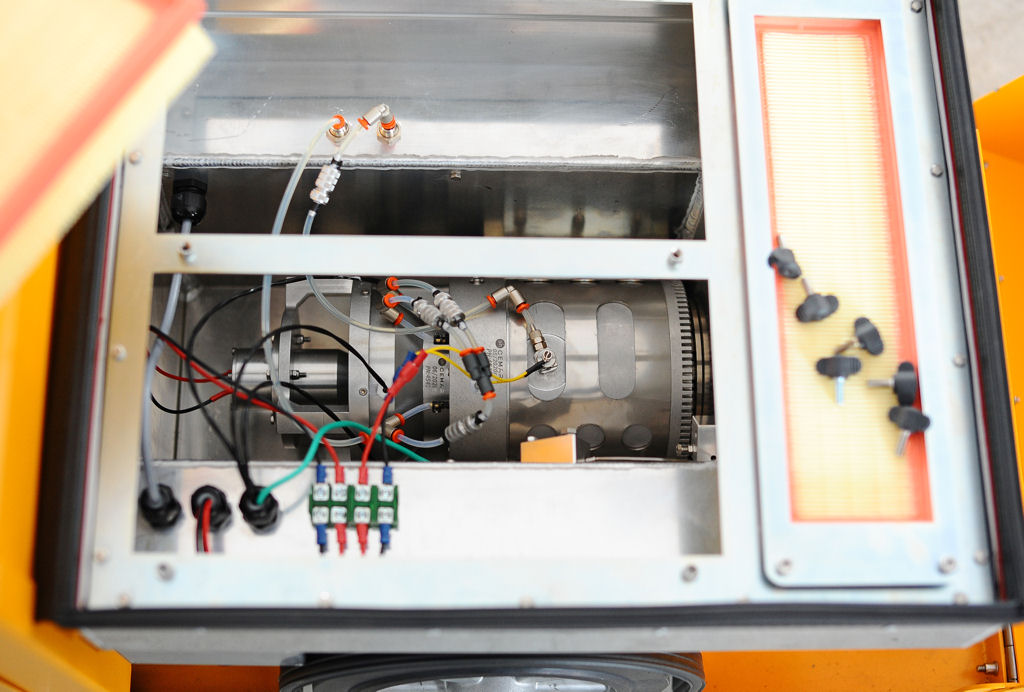

TURBINE

High-Performance Turbine Engine – Inspired by Aviation Technology

The powerful hot air blast generated by the Torgos dryer comes from its turbine engine, a compact version of the jet engines used in aviation. Operating at an incredible speed of 80,000 RPM—that’s over 1,000 rotations per second—this engine delivers unmatched performance.

To ensure durability and reliability, we manufacture the turbine in-house using advanced materials like Inconel, commonly used in aerospace and space industries. This allows the turbine to withstand extreme temperatures and rotational forces, making it exceptionally robust and long-lasting.

GPS and GSM

Smart Monitoring for Maximum Reliability

Due to the extremely high temperatures and rotational speeds, the Torgos dryer is a high-precision machine that requires advanced monitoring systems to ensure safe and reliable operation.

Key data is continuously transmitted to both the machine operator and a cloud-based service center via the integrated GSM system. This allows for real-time alerts in case of any issues, and even enables the service team to predict potential failures before they occur.

The intelligent software includes a self-learning system that monitors the condition of the bearings. It can detect early signs of wear and predict bearing failure, helping to prevent unexpected breakdowns and reduce downtime.

In addition, the built-in GPS system tracks the machine’s location and sends data to the cloud, allowing for remote monitoring and fleet management through a web-based platform.

WEB SYSTEM Troad.info

Dedicated Web Portal for Torgos Users

Torgos road dryer owners have access to a dedicated online portal designed to simplify machine management and service.

Through this platform, users can:

- Track the machine’s location via GPS

- Monitor operating hours

- Receive real-time error notifications

- Access service history and performance data

Service technicians can also remotely:

- Inspect machine status

- Diagnose issues

- Perform certain repairs online

This smart connectivity ensures faster response times, predictive maintenance, and minimal downtime, keeping your Torgos dryer running at peak performance.